The Float-Sink Method, 100% Effective!

![]()

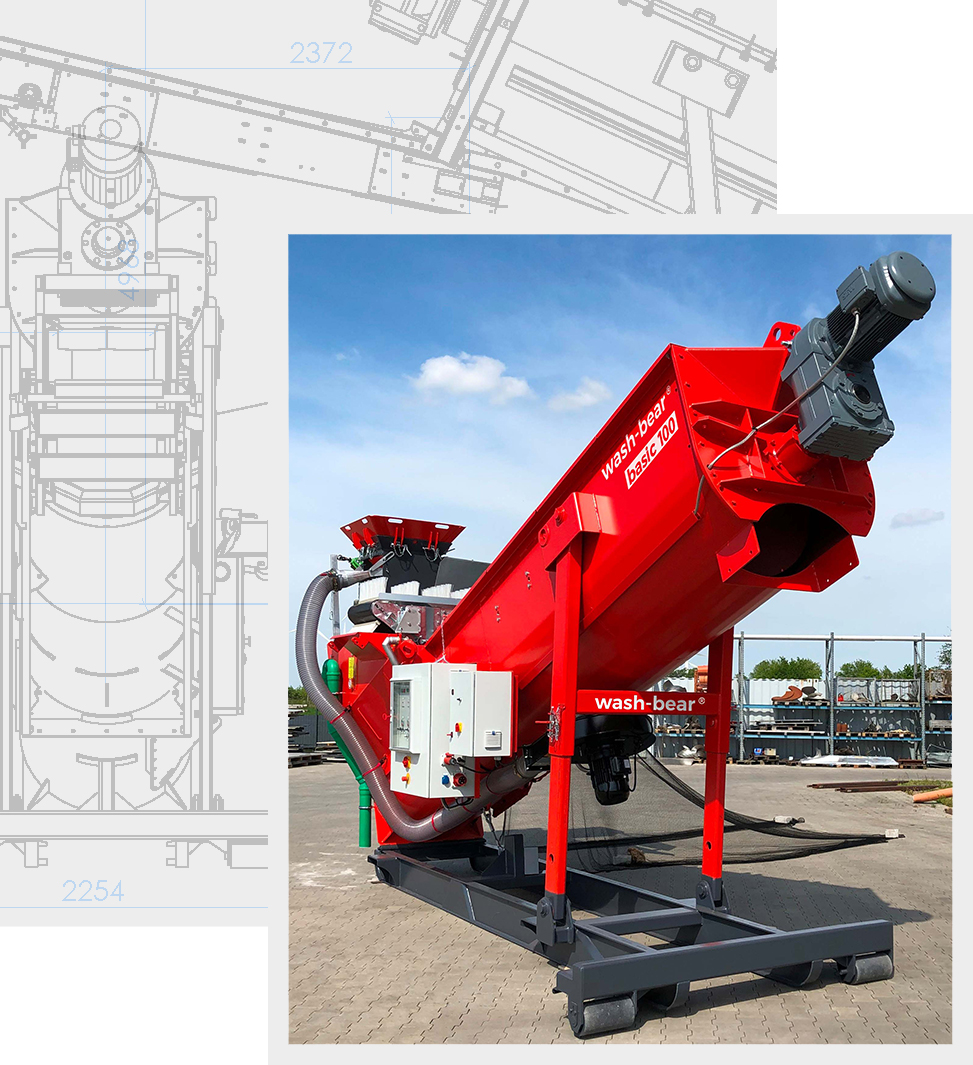

The wash-bear.

Over more than 15 years, the most versatile versions of the wash-bear® series have proven themselves hundreds of times under various requirements in construction material processing and recycling applications.

The robust concept of a purely hydromechanical separation of impurities from valuable mineral resources has proven to be superiorly efficient.

In a comprehensive relaunch, the available advancements have been consolidated into a new product generation.

The models are named wash-bear® "basic 100," "pro 150," and "pro 190." Additionally, there is now also a crawler-mobile fully self-contained working unit in the lineup, the wash-bear track190.

The wash-bear® "track 190" is equipped with a chain drive and its own 4.5 m long discharge conveyor. This is installed in such a way that it does not need to be dismantled during the plant's transport. Likewise, the optional wind sifter can remain on the plant during transport.

Properties

- Innovative screening system using the float-sink method

- No wastewater, only supplementation of process water

- High environmental compatibility due to low noise and dust emissions

Self-cleaning - Highly wear-resistant auger made from special alloy

- High production capacity

- Separating and screening in a single operation

- Low energy consumption

Your Advantages

- Extremely low operating and maintenance costs

- No generated process water residues

- Container-mobile special designs for specific applications

- Can be integrated into existing systems without major effort

- Reliably and cleanly separates feed material from lightweight substances

- Easy operation and maintenance

- Wear protection

- With integrated fill level control, manual sorting is eliminated.

Options

- Additional wind sifter in the feeding area

- Reduced auger quality for simple applications

- Hydraulic lifting function of the trough

- Hydraulic leveling device

- Plant with reverse-material discharge

- Integrated main discharge conveyor customer color

- Clean extension wet classification

Our wash-bear Series

![]()

The Different Models.

In addition to the ongoing optimization of process efficiency, operational reliability has always been a key focus. This has been realized, especially through easily manageable plant technology in deliberately robust and maintenance-free designs.

wash-bear basic100

Hook mobile lightweight separator

wash-bear pro150

Hook mobile lightweight separator

wash-bear pro190

Hook mobile lightweight separator