Lightweight separator

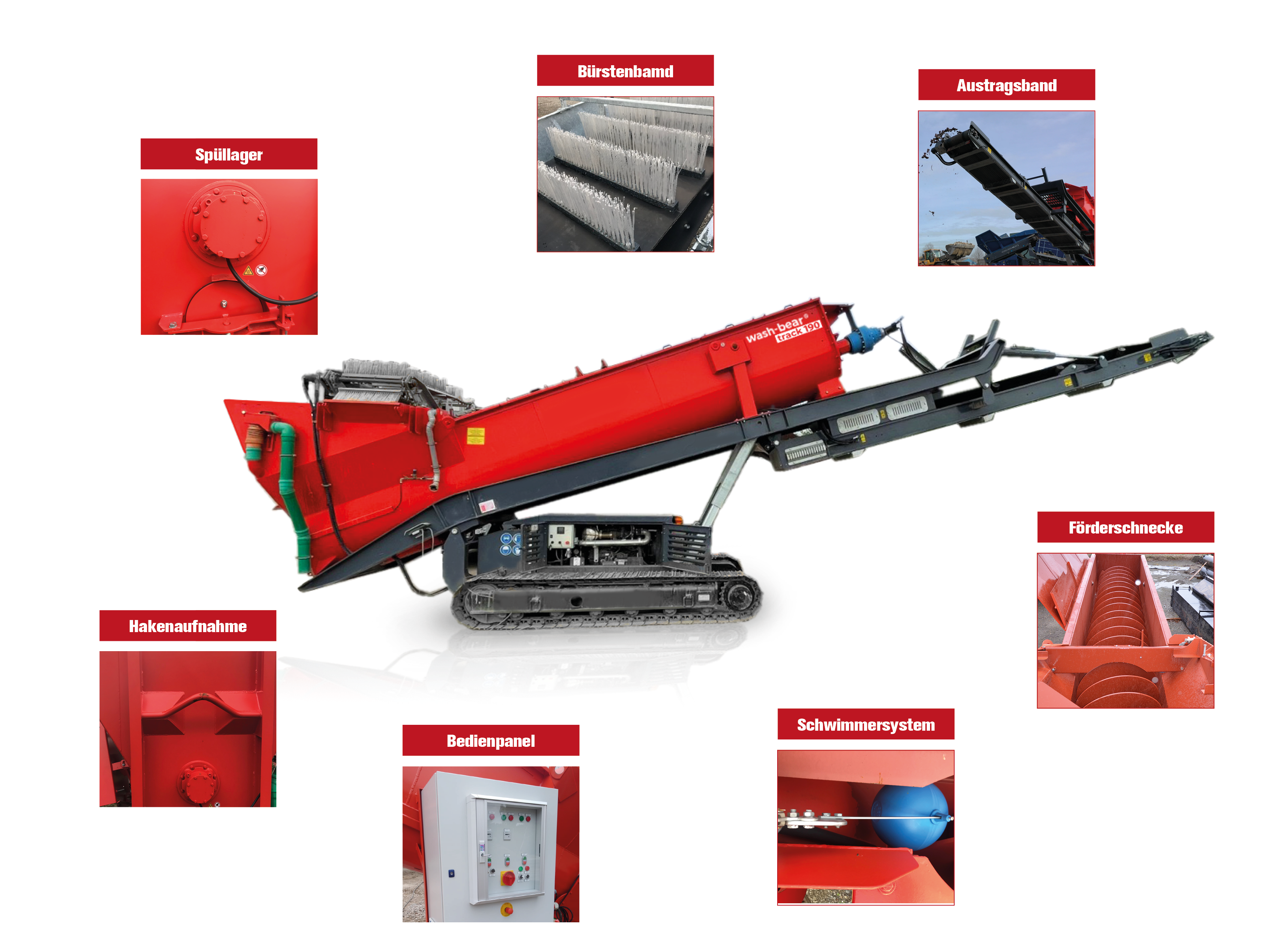

wash-bear track190.

The number represents the throughput capacity in tons per hour. The foundation of the simple and robust technology for the mechanical separation of lightweight substances such as aerated concrete, plastic, or organic material is based on the patented conveyor screw. It ensures nearly 100% efficiency. Through intelligent control, the rotational speed and pitch of the screw can be continuously adjusted, allowing for material dewatering. The discharge of the floating lightweight substances is continuous and automatic, facilitated by a specially designed brush conveyor belt for the wash-bear®. Additional separation options are provided, including an optional wind sifter.

The wash-bear track is equipped with a crawler track, making it even more mobile than its semi-mobile counterparts. Additionally, the wash-bear track is fitted with a 4.5-meter discharge conveyor, allowing for seamless integration into process workflows.

A combined chain with a mobile impact crusher and a double-deck post-screen, for example, enables complex process workflows. By washing the intermediate grain and recombining it with the screened fines, a higher-quality end product can be achieved.

Technical details

- Adjustable belt speed

- Low maintenance

- Self-cleaning

- The brush conveyor belt is used for discharging lightweight substances and as a flow regulator

- Double-helix screw conveyor made from special alloy to ensure long service life

- Conveys and dewaters the screened material in a single operation

- Optional and retrofittable at any time, even for existing plants

- Consisting of a blower and inlet chute

- Additional cleaning effect for recycled materials, as contaminants such as paper, films, grass tufts, or cable residues are also screened

The electrical components are located on the outside of the plant, well protected against splashing water, dust, and other external factors. Operation is extremely simple due to the clear layout of the control units.

The lightweight separator comes standard with an automatic fill level control. This functions similarly to a toilet tank – a float regulates the inflow and thus the water level in the separation area. This ensures that the water level is optimally adjusted for processing your recycled materials.

Fully mobile self-contained working unit, thanks crawler track.

Hydraulically extendable discharge conveyor.

wash-bear track190

Technische Daten.

| Production capacity | bis 190 t/h |

| Feed size | 4 - 120 mm |

| Drive power screw | 30 kW |

| Transport dimensions (LxWxH) | 11.000 mm x 2.450 mm x 3.300 mm |

| Weight | 16,5 t |

| Screw conveyor Ø | 1.000 mm |

| Tracks | ✔ |

| Discharge belt | 4.500 mm |